In this article you will find everything you need to know before buying protective eyewear, we will show you the most important points and what to look out for in order to have your eyes fully protected at all times.

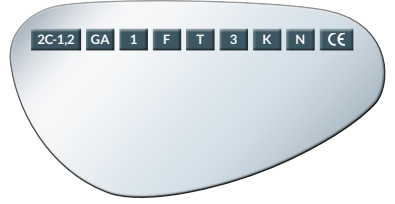

Spectacle marking

Protective eyewear must be marked in accordance with mandatory marking EU guideline EN 166 describes compulsory marking for safety spectacles.

The positioning of marking is not specified. It is important that marking on safety lenses does not obstruct the wearer’s field of vision.

Safety lens marking

Filter/tint protection grade

(UV radiation, colour coding)

ID mark of the manufacturer

Optical class

Mechanical strength

Mechanical strength in extreme temperatures

Field of application | combinations possible

Resistance to scratches

Anti – Fog

Conformity mark

Spectacle frame marking

Special temples for safety spectacles

Softflex Fit

The soft flexible loop of the Softflex Fit temple absorbs the tractive force of the frame and prevents pressure points developing behind the ear. Additionally, the rubberized temple tip, with its metal core, snugly accommodates the shape of the head and ensures that the safety spectacle fits perfectly and do not slip. The length-adjustable temple can also be adapted to the wearer’s individual anatomy.

Easy Fit

This all-purpose temple stabilizes the glasses with its anatomically-shaped temple and flexible material. It allows the wearing position of the safety spectacle to adjust automatically to the wearer without exerting uncomfortable pressure.

Easy Fit Soft – Temple with additional rubber lining

Together with its additional soft rubber lining, this optimized Easy Fit temple ensures an even better fit and comfortable positioning of the safety spectacle, especially in the event of heavy perspiration.

Basic Fit – Metal temple with slip-secure rubber tip

With its deformable metal core, this standard variant can be adjusted to the anatomical shape of every head.

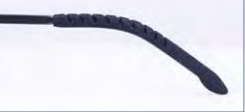

Ergo Fit

This ergonomically-shaped temple is modelled on the natural shape of the head. This means that the spectacles sit safely without exerting pressure. The special soft cushion on the temple tip protects the head from side impacts and also ensures a comfortable fit.

Soft Touch

The intelligent combination of two synthetic materials. The Soft Touch component, adjacent to the head and ear, provides a comfortable and slip-secure fit, whereas the somewhat more rigid synthetic part preserves the shape of the spectacle frame. By means of its length adjustability, the temple can also be adapted to the anatomical shape of the head.

Coating technology

Thanks to the ProCoat coating on the lenses, such as safety spectacles, we offer solutions adapted to every risk situation.

These are some of the most commonly used abbreviations to identify coating techniques:

- HC – Hard Coating

- AF – Anti-fog

- AS – Anti-static

- SAR – Super Anti-Reflex

CLEAR HC – super scratch resistant

This special lacquer coating greatly enhances scratch-resistance on both surfaces of the lens. The hard layer also improves protection against chemical attack.

Areas of application: this coating is suitable for environments in which the safety spectacles need frequent

cleaning. Dust and grit are just as easily removed as thin

and viscous fluids

CLEAR AF AS – anti-fog, scratch-resistant, antistatic

This coating makes safety lens scratch-resistant, anti-fog and antistatic on both the inner and outer surfaces. In particular, a combination of anti-fog and antistatic effects ensures clear vision for long periods. The lens surfaces remain dirt-free for longer and are more easily cleaned

Areas of application: this coating is suitable for work in constantly changing temperatures, when perspiration build-up is a problem and/or for activities in moist, warm and dusty environments.

CLEAR AFP – super scratch-resistant, anti-fog, antistatic

The perfect coating combination of CLEAR HC and CLEAR AF AS with enhanced scratch-resistance

and anti-fog on both the inner and outer surfaces of the glasses. This improved anti-fog effect ensures that the glasses are fog resistant even with extreme temperature fluctuations. The enhanced scratch-resistance provides greater protection from external effects.

Areas of application: this coating is suitable for environments in which the safety spectacles need to be cleaned frequently. Dust and grit are just as easily removed as thin and viscous fluids. Additionally, this coating is suitable for work in constantly changing temperatures, when perspiration build-up is a problem and/or for activities in moist, warm and dusty environments.

CLEAR SAR – super anti-reflection

CLEAR SAR eliminates practically all distracting reflections. Particularly in working environments where safety spectacles have to be worn under bright artificial light, this super anti-reflection effect helps prevent tired eyes and supports concentration. With their additional hard layer, safety lenses with CLEAR SAR are also scratch and chemical-resistant.

Areas of application: this coating is particularly suited to production areas where safety spectacles have to be worn and to industrial environments with strong artificial light, e.g. assembly shops.

Safety lens materials and their properties

The right material for every requirement!

The choice of the right safety-lens material depends on the intended use, working environment and field of activity. The safety lenses are made from both plastic and mineral glass.

Plastic

Plastic lenses are particularly useful because they weigh so little. Safety lenses made of Polycarbonate are especially good at protecting against mechanical hazards. Acetate lenses are particularly resistant to chemical attack.

Polycarbonate (PC)

Properties Polycarbonate:

- Very low weight

- Very high mechanical impact strength

- 100 % UV protection

- Enhanced scratch-resistance due to coated surfaces

- Low spark-penetration in grinding and welding activities

Acetate (AC)

Properties Acetate:

- Very low weight

- 100 % UV protection

- Very good resistance to chemicals

Mineral glass

Safety lenses made of mineral glass are recommended for very dusty and sandy working environments, as this material exhibits the highest resistance to scratching.

Hard Glass

Properties Hard Glass:

- Very high scratch-resistance

- Chemical-resistant

- Spark penetration is possible in grinding and welding activities