If you like welding or if you are directly involved in it, you have probably asked yourself more than once… how many types of welding exist and how do you really know which one is the most suitable for each type of work?

These are very common questions that everyone has asked themselves on more than one occasion. The oldest welding technique is that which is achieved by means of the heat necessary to melt two metals together and join them when they have cooled down. However, over the years, many new techniques have appeared which are more appropriate than others depending on the material we want to work with, the cost, the type of final result we want to obtain…

Below, we will name some of the most common types of welding and explain how they work and their main uses. We must remember that welding is a risky activity, so we always recommend the best protection for welding, such as a good welding mask and welding gloves to protect our hands from possible sparks and burns.

But first of all, what is welding? We talk about welding when we refer to the fusion and union of two or more materials through the use of heat, in order to create a solid union between them.

Types of welding

These are some of the main types of welding used in the welding world.

Electric arc welding

One of the most common types of welding used by welders, this type of electric welding uses a source of electrical energy to melt metals easily. Within this type of welding we can include:

- TIG welding

- MIG welding

- Mig mag welding

- Electrode welding

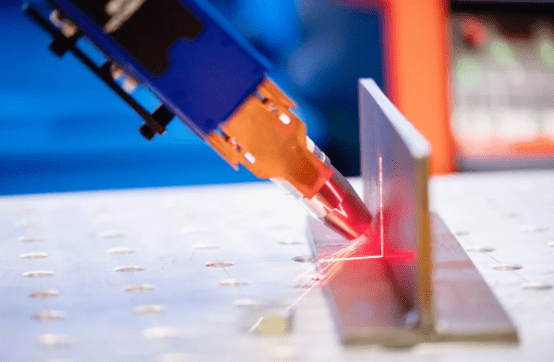

Laser welding

In this process, a powerful laser melts a surface or material in order to join it to another, normally the materials being worked on are metals or plastics. A great advantage is that they are very easy to program and configure, they do not require a great deal of experience on the part of the welder and are easy to adapt to each job.

Laser welding has a penetration power of up to 5 mm, with the capacity to weld at high speeds, achieving very fast and efficient welds. Another very interesting advantage is the low generation of fumes produced by this type of welding, despite this, we recommend always wearing a good mask to prevent possible health problems, it does not leave welding marks and eliminates the need to polish after the welding process, which saves us a lot of time.

Laser welding is ideal for the manufacture of large unitary parts, large series and with good finishes, for the railway industry or for parts for the aeronautical industry, for example.

Gas welding or autogenous welding

Autogenous welding was one of the first fusion welding processes to be developed for many years, however, nowadays, arc welding has been gaining prominence and is the most widely used by welders.

Autogenous welding is used for brazing and soldering, as well as for cutting steel.

Oxyacetylene welding is a type of autogenous welding. For its operation, a torch fed with gas and oxygen as fuel is used, this is capable of withstanding very high temperatures and creates a constant flame capable of melting the metals. By means of this technique we can weld copper, steel, aluminium… autogenous welding takes a long time to cool down and has a low cost.