What is silicosis?

Silicosis is an incurable disease that affects the lungs of people who inhale crystalline silica particles. Exposure to this material is common in many workplaces, such as in the construction, mining and manufacturing industries. Recently, the Cosentino case has demonstrated the importance of adequate respiratory protection for workers exposed to crystalline silica, as well as the need to make the use of such personal protective equipment mandatory in all jobs that may involve exposure to this material.

Silicosis develops gradually as crystalline silica particles accumulate in the lungs, causing scarring and irreversible damage with little life expectancy. Symptoms can take years to appear, meaning that many workers may be exposed to crystalline silica for years before being diagnosed. Symptoms include chronic coughing, shortness of breath and fatigue, and the disease can be fatal in severe cases.

The Cosentino scandal

The “Cosentino case” is a sad example of how the lack of effective respiratory protection can have catastrophic consequences for workers’ health. The company, known for its production of stone and quartz surfaces, has been the subject of a scandal after it was discovered that almost 1900 of the company’s workers have been diagnosed with silicosis, an incurable and potentially fatal lung disease.

The Cosentino case is an important reminder of the need for proper respiratory protection in all work involving exposure to crystalline silica. Crystalline silica is found in many materials used in construction and manufacturing, and is known to be a major cause of silicosis worldwide.

How can we prevent such a disaster from happening again?

In view of what happened in the Cosentino case, it is obvious that simple compliance with a regulation by respiratory protection equipment is not enough. Although the Cosentino workers had certified respirators, they were still affected by silicosis. The reason is quite clear: A respiratory protective mask that does not fit the user’s face perfectly and does not achieve a perfect facial seal does not guarantee safe respiratory protection, no matter how effective the filter is. A mask that does not fit the operator’s face properly leads to leaks that can be very harmful, as particles above the permitted levels can enter the respirator.

Therefore, in some EU countries such as Ireland, Belgium, or Italy, every operator is required to wear a respiratory protector that is subjected to a face fit test (Fit test – performed according to 29 CFR 1910.134 or similar protocols) that certifies that the respiratory protection is adequate. Not only does the respiratory protective equipment have to be CE certified and comply with the applicable regulations, but the respiratory protective equipment must also be suitable for the user.

Although such fit tests are not a mandatory requirement in Spain, we believe that this test is the only possible way to guarantee real and effective respiratory protection for an operator.

Based on years of experience with numerous facial adjustment tests, certain patterns are quite evident:

- A bearded operator will not be able to get the mask to fit tightly enough on his face to keep total inward leakage below maximum safe levels. The larger the beard size, the less or no effectiveness of a mask.

- Generally, the narrower the face, the more difficult it is to achieve a secure fit and face seal. Most masks on the market are too large for smaller faces.

- While most respirators have some mechanical means of achieving facial fit, the most common being the use of metal rods in the nose bridge area, this area is possibly one of the most critical in terms of ensuring that there is no excessive leakage. It is common to see workers wearing masks and goggles with fogged lenses due to the use of the masks. But what must be understood is that if a lens fogs up when you exhale when you wear a respirator, it is because the hot air you expel when you exhale is blown upwards where there is a poor fit to the lens. Since it is a fact that air circulates where there is the least resistance, if the air exits through a leaky area when we breathe out, when we breathe in, it will also enter through the same place without passing through the filter.

- Many workers do not know how to put on a mask properly and the fit tests are used as an opportunity to inform the operator how to fit a mask correctly. But it is also noted that, despite following all the instructions to achieve a good facial fit, that fit can be adversely affected by speech, bending over or any movement of the face. While a mask may initially fit correctly, daily activity has a significant impact on the effectiveness of the fit.

How can we protect ourselves from silicosis?

Given the seriousness of the risk posed by exposure to silica and being aware of the problem of adjusting respiratory protection equipment, the need for the use of positive pressure respiratory protection equipment is clear. In other words, individual respiratory protection equipment that prevents contaminated air from entering the mouth and nose area of the worker, even though there may be leaks towards the inside.

Only equipment with filtered air supply to the mouth and nose area will be able to prevent the penetration of contaminants.

On the other hand, there are other tools to determine the level of protection that respiratory protective equipment can provide. One of them is the Nominal Protection Factor (NPF).

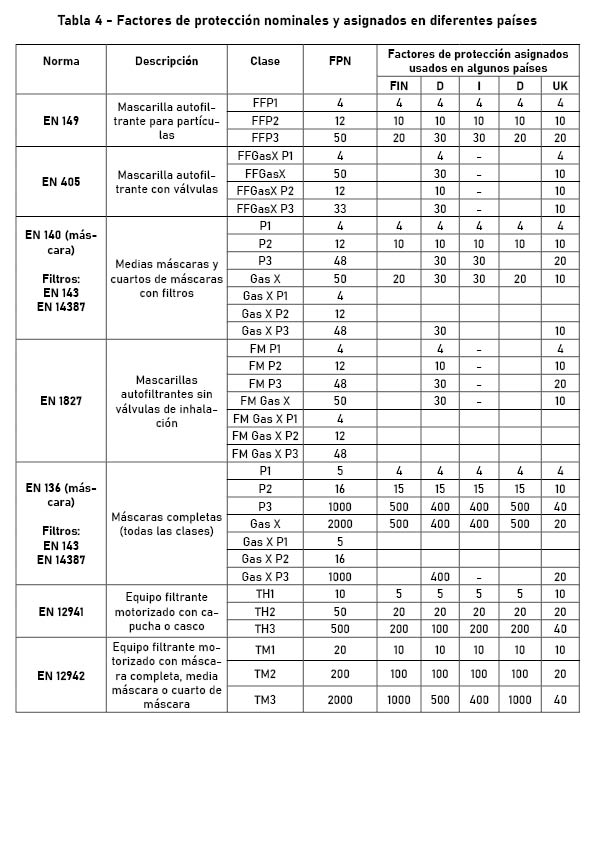

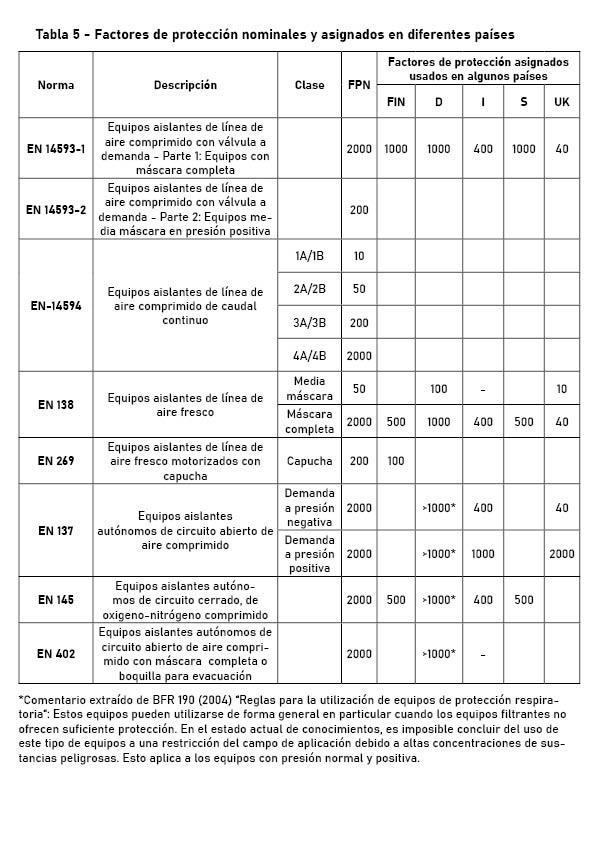

The Nominal Protection Factor is the level of protection expected from different types of respiratory protective equipment. In other words, it is the level of protection that a specific user can achieve with the PPE. It is calculated by making the ratio between the ambient concentration of a substance in the air and the concentration of the same substance inside the equipment in the user’s breathing zone (NPPF = External cc. / Internal cc.).

Depending on the application standard and its class, the following nominal protection factors are established:

The higher the number, the greater the protection. A nominal protection factor of 4 means that the respiratory protective equipment should protect the operator in areas where the concentration of contaminant matter does not exceed 4 times the legal maximum permitted while a nominal protection factor of 2000 means that the respiratory protective equipment could be used in areas where the contamination is 2000 times higher than the maximum permitted so as not to be harmful.

On the basis of these elements, we can establish a range of respiratory protective equipment that will be able to guarantee full protection against silica.

With the highest nominal protection factor – class TM3 according to EN12942 FPN: 2000 – Dacar offers the Synchro range of face masks and half masks with built-in motor fan, available in the Sync01, Sync09 and Sync11 models.

But there are other valid alternatives, such as the CleanAIR motor-ventilated assemblies, which offer a nominal protection factor of 500 according to EN12941 in class TH3. In particular, we can recommend the Ready 2 work CleanAIR AerGO & UniMask set.

Apart from implementing appropriate respiratory protective equipment, it is important that companies provide adequate training and education on respiratory protection and other occupational risk prevention measures for their workers. It is also necessary that monitoring measures are put in place to ensure that regulations are complied with and that the necessary measures are taken to protect the health and safety of workers.

In conclusion, the Cosentino case is a grim reminder of the dangers of exposure to crystalline silica and the importance of proper respiratory protection in the workplace. Employers need to take measures to protect their workers and regulations need to be implemented to enforce respiratory protection in all jobs that may involve exposure to this hazardous material. The health of workers must be the top priority in any workplace, and the prevention of silicosis is a critical component of that effort.

We provide you with two links to news related to the Cosentino Case: